Dongguan Lean Industry Co., Ltd. is a stock enterprise in Dongguan since 2015.

Our service for one-stop customize projects

Plastic Injection molds‖Plastic molding parts‖Precision machining parts‖Precision progressive die parts

Common injection molding materials

Plastic:PA66/PA6/PA46/PA6T/PA9T/ABS/PC+ABS/PBT/LCP/PPS/PE...etc;

Thermosetting injeciton materials:Bakelite PF2A5/DAP/T378...etc

Powder injection materials:Ceramics AL2O3.ZRO2...etc

ShenZhen KjnMold Co.,Limited. (hereafter as "KjnMold") is a mould plant founded by Daniel Hu, an experienced and passionate mechanical design engineer who has dedicated in mould industry for more than 25 years.

KjnMold is registered in 1998 in Shenzhen, a city in Guangdong province in China, to fulfill the growing needs from the domestic and oversea clients who pursue the best quality-price-ratio and innovation in the product design and manufacturing.

KjnMold provides professional one-stop services according to clients’ requirements. We manufacture from provided drawings, and design new mould according to product sample or specification, with wide range of injection raw materials from common plastic, bakelite, to ceramics. We can also produce parts from client approved moulds, process finish treatment including: painting, silk screen printing, hot stamping, electroplating; and execute sub-assembly and packing for shipment if needed.

We are proud of our nearly 100% customer satisfaction due to several distinguishing factors. On top of it, we are in a not big but agile scale which can move quickly to solve problems and complete jobs while other larger companies get bogged down. Because of this, we have maintained stable cooperative relationship with well-known companies such as Huawei, Gree, FAW, Volkswagen and so on.

We support your business success with our expertise and passion in mould!

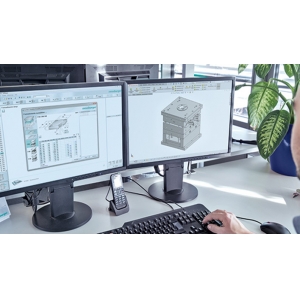

KjnMold has the capabilities and skills to support at any phase of your product development process. We can provide complete mould design from a sketch from your marketing team; We can assist in completing designs for your engineering team; We can provide the DFM advice to support your design for a successful production; We can also re-design for a product cost reduction call from your operation team to prolong the product life in market.

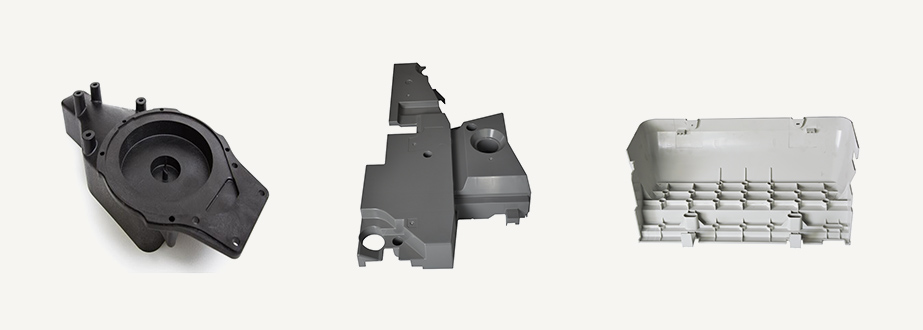

We mainly support plastic parts, precision progressive die parts and precision hardware processing parts for automotive, consumer appliances and engineering machinery, in the forms of below:

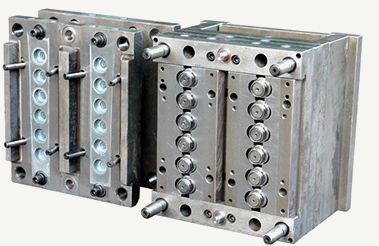

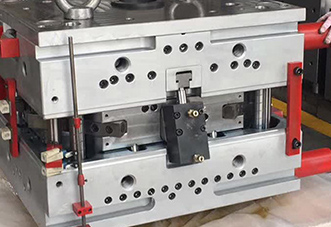

Plastic injection moulds

Plastic molding Products

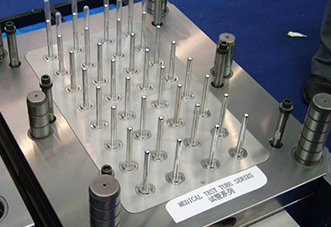

Precision CNC machining parts

There are some common injection molding materials we are applying to our projects but not limited to:

Plastic: PA66/PA6/PA46/PA6T/PA9T/ABS/PC+ABS/PBT/LCP/PPS/PE...etc;

Phenolic Resin injection materials: Phenolic Resin PF2A5/DAP/T378...etc

Powder injection materials: Ceramics AL2O3.ZRO2...etc

There are some key steps that we recommend to be engaged in the product development process, which will secure the efficiency and value of one-stop services to your product delivery:

Product design support- DFM (Design for Manufacturability) report, a mould design assessment report complying with client's requirements

Mould design, modification and maintenance - Thorough consideration to mould construction, gates, runners, cooling channels and mechanisms to optimize the tool life

Injection molding parts - Part validation within spec in dimension accuracy, performance, and materials

Customized packaging - Packing to budget and design as needed

Global logistics and transportation - Superior geographical location and transportation services

Our molding services are always expanding in order to meet the ever-changing needs of product developers and engineers around the world.

KjnMold is your accountable mould supplier with continuous drive in providing you with our:

One-Stop Services — We are with a unique advantage in offering innovative solutions to mould, parts and secondary operations for a wide range of industries. That is, we provide one-stop service to your product solution.

Quality Delivery — We implement TQM (total quality management) through the entire design and manufacturing process and have successfully achieved ISO 9001:2015. The team is with strong sense of quality delivery to save each cent for clients.

Speed — Our tool and die manufacturing departments allow us to provide a quick turnaround on new product development process. Our goal is to maximize production, minimize cycle time, and prolong mould life in one streamlined process.

Your Inputs

For Plastic Injection Mould and Molding Parts Requests

Product Design File (3D in STP or X_T, and/or 2D in DWG or PDF)

Mould Design Requirements (cavity, steel, core, stopper plate, etc.)

Mould Standard (DME, Hasco, MISUMI)

Material Requirements and MOQ (plastic, bakelite, ceramics or other special)

Finish Treatment (painting, silk screen printing, hot stamping, electroplating, ect. )

Product Acceptance Criteria (Quality Standard)

For Precision CNC Machining Parts Requests

Product Design File (3D in STP or X_T, and/or 2D in DWG or PDF)

Material Requirements and MOQ (plastic, bakelite, ceramics or other special)

Product Acceptance Criteria (Quality Standard) and Finish Treatment

Our Output

For Plastic Injection Mould and Molding Parts Requests

Formal Quote and DFM Analysis Report

Mould Design Assets (3D/2D/BOM)

Mould Trial Samples (T0/T1/T2..)

Test Reports (Mould, Product and Packaging per spec)

Mould and Parts Delivery (Airfreight or Shipping)

For Precision CNC Machining Parts Requests

Samples and Products

Out-going Inspection Reports

Mould Design | Injection

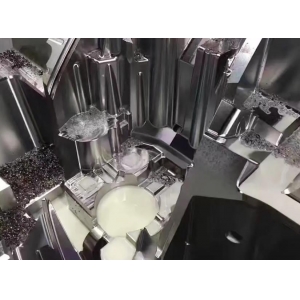

KjnMold has the capacity to run products in sizes up to 500mm in a large array of materials. Among the thermoplastic materials utilized are standards such as ABS, PVC, Acrylic and Polycarbonate..etc. Also used are specialized materials that can provide super high impact strength, withstand high or low temperature environments, or provide ESD protection. Many materials used are approved by various regulatory organizations such as FCC, FDA, NSF and UL.We also perform many post-processing operations including machining, assembly, and finishing. All operations are subject to rigid quality controls to ensure on time deliveries to clients. In addition, we maintain a network of stocking distributors, specialized fabricators, and precision machine shops that are constantly audited to maintain quality standards. This allows them to provide a full range of services to meet any plastic part requirements.

Our CNC machining process uses 3- and 5-axis axis milling along with turning with live tooling to machine parts from more than 30 engineering-grade plastic and metal materials. The result is functional parts suitable for form and fit testing, jigs and fixtures, and end-use applications. Our automated CNC machining process can manufacture and ship up to 200 parts in as fast as one day.

Lean industry

Lean industry

We are proud of our nearly 100% customer satisfaction due to several distinguish factors

High Precision

Quality

Cost Reduction

KjnMold is committed to provide high-quality moulds, molding parts and outstanding secondary operations to satisfy our clients. With strong sense of quality control, the management team keeps investing high-quality assurance equipment, management system, talents and sustainability to the environments.

High Standard -- We implement TQM (total quality management) through the entire design and manufacturing process and have successfully achieved ISO 9001:2015.

Advanced Technology Supports -- Our industry leading CNC, WIRE CUT and EDM processing equipments allow us to secure the standard accuracies of +/- 0.005” of the tool. We use only high stability alloys and quality mould components to ensure reliable operation during the injection molding process.

Process-oriented -- We have streamlined the mould design and manufacturing process, with each step controlled and supervised in-house. This allows us to control every aspect of quality assurance elements from start to end with consistency in delivery, and also makes it possible to accommodate customer requested engineering changes efficiently.

Compliance and Safety -- LeanIndustry is fully aware of the importance of health and safety. Our moulds are designed and built to meet relevant safety standards. Our processes and procedures are designed not only to meet legal requirements but also to effectively maintain a healthy, safe and secure working environment. The company’s health and safety policy sets our commitment and outlines our approach to effective health and safety management.

KjnMold has injection moulding machines ranging from 50 ton to 1,000 ton fully automated production. Our mould workshop is fully equipped with leading CNC, Wire Cut and EDM processing equipments to manufacture injection moulds and machining parts in-house, with HASCO and DME standard applied for oversea clients according to customer requirements.

Our products are mainly exported to United States, Canada, Brazil, Mexico, Uruguay, Argentina, Germany, Czech, United Kingdom, France, Spain, Portugal, Turkey, Poland, Israel and other countries.

Our highly skilled designers and mould engineers handle complex and extremely time sensitive projects daily. Our state-of-the-art facilities are fully equipped and capable of manufacturing precision moulds and injection moulded parts in a matter of days.

KjnMold(Since1998) and Subcompany:LeanIndustry(Since 2015) has successfully achieved ISO 9001:2015 by effectively implementing total quality management system through the entire design and manufacturing process.